contact number:

TARGET SECTORS

TARGET SECTORS

-

automotive

The increase in weight through required engine efficiency measures as well as electrification in the automotive industry triggers an additional need for cost-efficient lightweight solutions. New process and material developments enable a wide range of high-volume applications for fiber composite materials

-

aerospace

The use of lightweight materials in aerospace applications has two main drivers: reduction of fuel consumption & related costs and increase of passenger/cargo load per flight. New material and process developments enable cost-efficient lightweight solutions by using highly automated and robust production technologies

-

transportation

Sector specific development of composite lightweight solutions for the growing transportation market like train, truck, bus or marine application to enable a sustainable transport of goods and passengers

-

industrial application & construction

The consistent use of lightweight materials enables sustainable and energy-efficient in industrial application & construction, adapted to the respective requirements of the entire system.

TECHNOLOGIES & EQUIPMENT

TECHNOLOGIES & EQUIPMENT

R&D SERVICES

R&D SERVICES

-

PROCESS

Innovative production technologies for high volume applications

LEARN MORE -

MATERIALS

Sustainable materials solutions based on Thermoplastic & Thermoset composites

LEARN MORE -

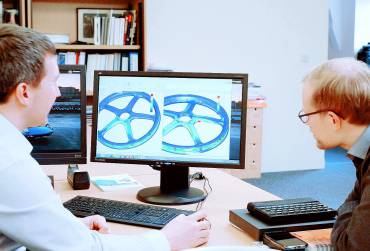

ENGINEERING

Engineering & part design for composite lightweight solutions

LEARN MORE -

OTHER SERVICES

Other services related to composite solutions like consulting, training, IP and benchmarking analysis

LEARN MORE

NEWS CENTER

NEWS CENTER

-

ACTC Participated in the 8th China Lightweight Vehicle Summit 2021 and Shared Practical Experience with the Industry

From April 22 to 23, the 8th China Automotive Lightweight International Summit 2021 was held in Shanghai.

05.May.2021READ MORE -

Development of Carbon Fiber Aircraft Door Edge Member

Fraunhofer ICT Works Together with HRC to Promote HP-RTM in Aerospace Applications

Recently, Fraunhofer ICT and HRC jointly initiated the advanced research project of carbon fiber aircraft door edge member...

11.November.2020READ MORE -

VirtualSMC: Efficient Virtual Process Chain for SMC Materials for Industrial Applications

High material costs, difficult to control manufacturing processes, and the challenging …

06.June.2020READ MORE

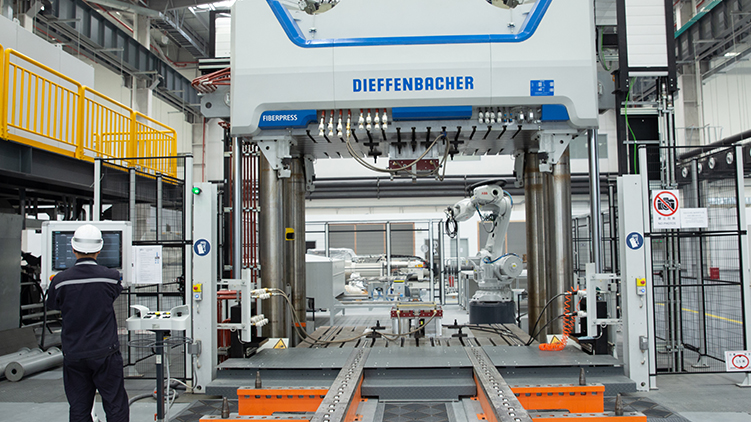

ACTC, the first R&D center in China for applied research dedicated to thermoset and thermoplastic composite technologies in future lightweight applications, is an open platform for high-performance composites with focus on mass production technologies

8,000 Sqm

Building

20 Million Euro

Investment

Located

In Changshu