contact number:

Thermoplastic Compression Molding

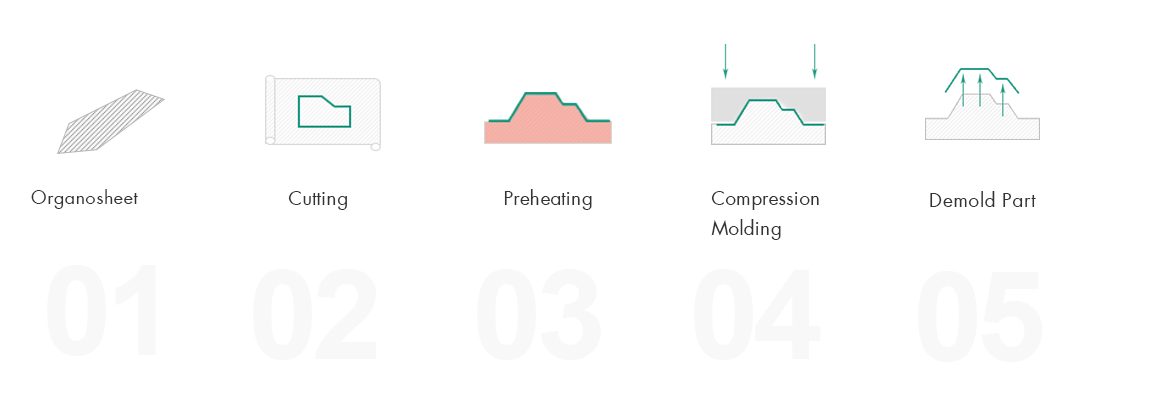

Thermoplastic Compression Molding is a manufacturing process that a thermoplastic prepreg (organosheet) is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to become a usable product. At ACTC, we have workstation with high level automation where a high-accuracy press, an IR oven and a robot are installed. We have the capability to mold organosheet to form different products at short cycle time.

Process Features

-

High automation

High automation -

Semi-structural part

Semi-structural part -

1-3 mins/part

1-3 mins/part -

Cost-efficient tooling

Cost-efficient tooling -

Good mechanical properties

Good mechanical properties

Process Flow