contact number:

SMC & Prepreg Development

■ SMC

SMC (sheet molding compound) material have been known as resin matrix composite for several decades in many industries, traditionally defined as comprising unsaturated polyester (UP) or vinyl ester(VE), chopped glass fiber and other additives. Due to the recent requirement from OEMs, ACTC aims to develop different kinds of SMC as follows:

◆ Low Density SMC

to reduce the weight of final part by replacing traditional SMC filler like calcium carbonate or alumina tri-hydrate.

◆ Class A SMC

to achieve high surface quality SMC in automotive industry by optimizing the formulation of SMC.

◆ C-SMC

to improve the mechanical properties of SMC and broaden the SMC beyond the conventional usage by using carbon fibers, especially for structural application.

- Large tow carbon fiber

- Recycled carbon fiber

◆ New Resins and Compounds SMC

to reduce the emission of VOC and to obtain low flammability without adding filler compared to conventional SMC by using new resin system.

- Thermosetting (Epoxy, Phenolic)

- Thermoplastic

■ Prepreg

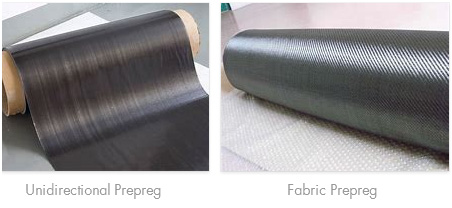

ACTC aims to develop two kinds of prepreg: unidirectional and fabric. These two kinds of materials are able to be utilized in conjunction with chopped fiber materials for local strengthening. They can also be used as stand-alone products.