contact number:

Automated Tape Laying

Automated tape laying, also known as ATL, is a very well- developed automated manufacturing process technique in the field of composites. ATL originates from manual deposition of UD tape, only taking it to higher level in terms of speed and process control. With the development of new tape laying technology that helps to minimize the cutting scrap and to maximize material throughput, a more efficient and more economically favorable way of tape laying was introduced: the state of art technology of Fiberforge tape laying, combining speed and cost- saving together.

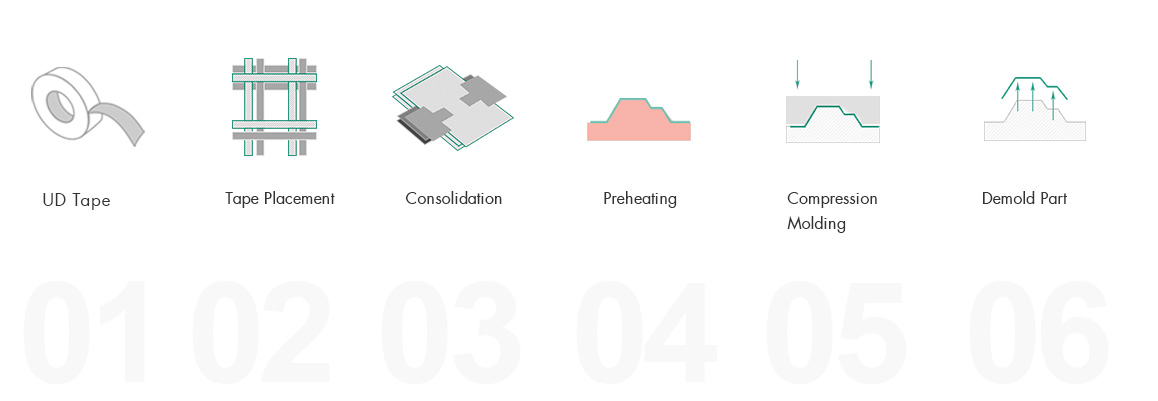

UD tapes are transported from the spool to the feeding chute, then cut into set length and angle, transferring to rotational table, forming certain layup shape and then weld if necessary. The net shaped layup then undergoes consolidation in Fibercon. As a sequel of Fiberforge welded tape- layup, Fibercon is served as the consolidation station for the tape, turning tailored blank into a solid organosheet of various thickness. The process is easily divided into three steps: first, load the material onto the bottom plate and manually close top plate; second, heat the tape- layup until the temperature reaches over melding temperature so that the resin and fiber can be melded evenly; third, the consolidation and cooling process refrigerates the consolidated material, which now becomes organosheet.

Process Features

-

Fast tape lay-up (2.7 sec/tape)

Fast tape lay-up (2.7 sec/tape) -

High design freedom

High design freedom -

Flexible material lay-up

Flexible material lay-up -

Low material scrap rate

Low material scrap rate

Process Flow